DIG-DOG Mini Wheel Loader

DIG-DOG Mini Wheel LoaderWheel loaders, as core equipment in the industrial and construction sectors, have a crucial impact on operational costs and environmental performance due to their fuel economy. This article delves into the underlying reasons for high fuel consumption in wheel loaders and provides targeted fuel-saving strategies to assist purchasers in making more economically informed decisions.

1.Equipment Design and Configuration: Unreasonable equipment design and configuration, such as overweight or underweight bodies, mismatched engines and transmission systems, can lead to reduced fuel economy.

2.Engine Performance: Key parameters like efficiency, power, and torque of the engine directly determine the fuel consumption of wheel loaders. Inefficient or improperly matched engines can increase fuel consumption.

3.Operating Habits and Driver Skills: Drivers' driving habits, operational skills, and experience significantly impact fuel economy. Improper operations can lead to fuel waste.

4.Maintenance and Servicing Conditions: Regular maintenance and servicing are crucial for keeping engines and fuel systems in good condition. Lack of maintenance can lead to decreased fuel economy.

1.Optimize Equipment Selection: Choose appropriate equipment models and configurations based on actual needs to ensure that the equipment design matches the practical work requirements.

2.Select High-Performance Engines: Use engines with high fuel efficiency and strong power to ensure that engine performance matches the equipment's needs.

3.Driver Training and Skill Improvement: Provide professional training to drivers to enhance their operational skills and environmental awareness, reducing unnecessary fuel consumption.

4.Strengthen Maintenance and Servicing: Establish a comprehensive equipment maintenance system to ensure timely and professional care and repairs, maintaining the optimal condition of engines and fuel systems.

DIG-DOG Wheel Loader With Pitchfork Attachment

DIG-DOG Wheel Loader With Pitchfork Attachment

The fuel economy of wheel loaders is influenced by various factors, including equipment design and configuration, engine performance, operating habits and driver skills, and maintenance and servicing conditions. By optimizing equipment selection, choosing high-performance engines, enhancing driver training and skills, and strengthening maintenance and servicing, the fuel economy of wheel loaders can be effectively improved. When making purchase decisions, considering these factors comprehensively will help make more economically and environmentally friendly choices.

DIG-DOG wheel loaders are widely recognized by users in the industry for their excellent fuel economy, superior performance, and stable quality. We recommend considering DIG-DOG wheel loaders as your preferred choice when making a purchase decision. If you have any questions regarding the purchase, usage, or maintenance of DIG-DOG wheel loaders, please feel free to contact our online experts. We will be happy to assist you and provide answers to your questions. Together, let's create a more economically and environmentally friendly future!

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

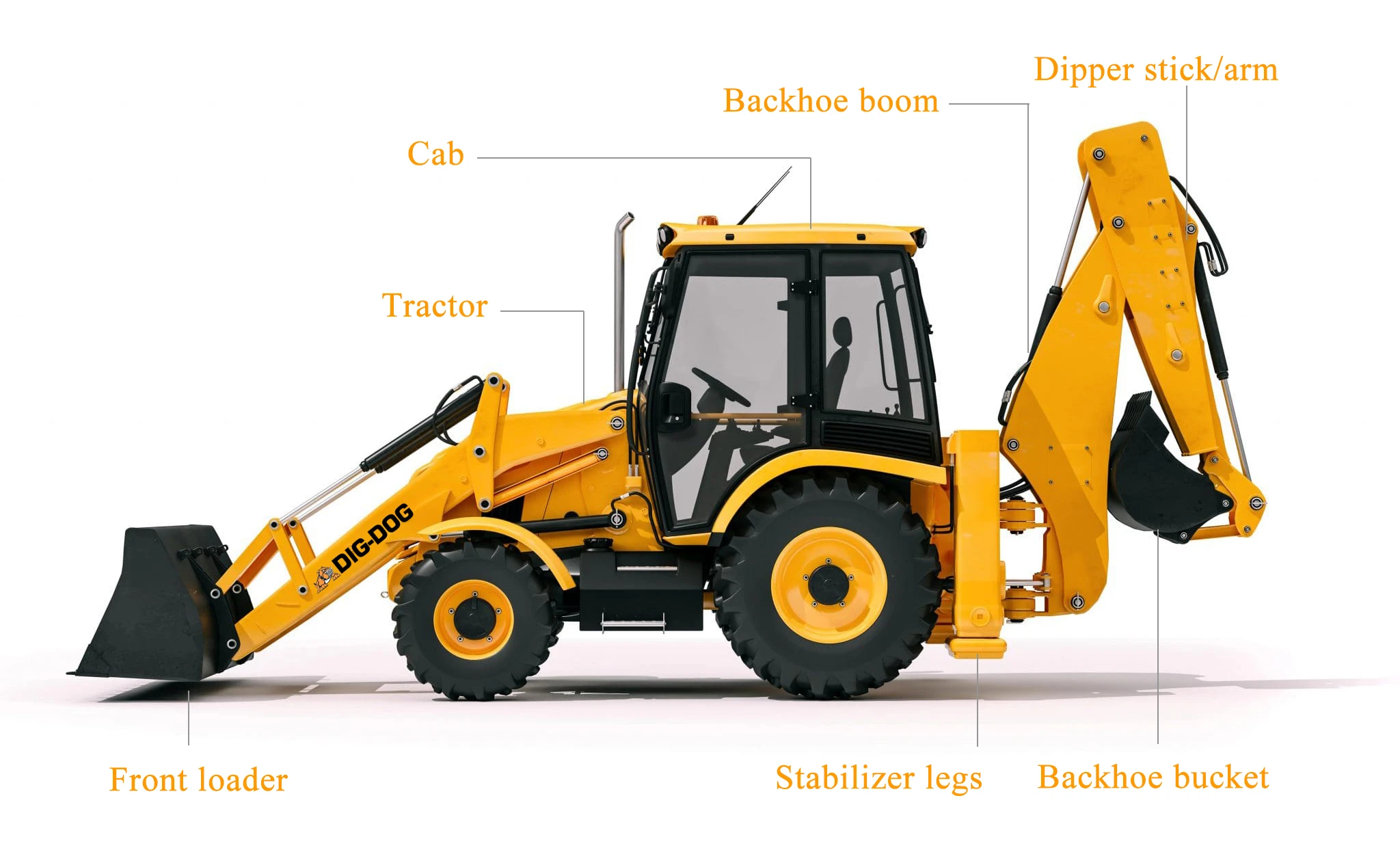

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?

Choosing the Right Loader Truck for Your Business Needs

Choosing the Right Loader Truck for Your Business Needs