Any equipment is a combination of many different parts, each part plays a vital role in the operation of the equipment, in the general structure of the loader, the drive axle mainly has a bridge shell, main drive, active spiral bevel gear, differential, large spiral bevel gear, breathable pipe, half shaft, disc brake, wheel side reducer, etc., the loader drive axle is divided into front and rear axle, the front axle The active spiral bevel gear is left-handed, and the active spiral bevel gear of the rear axle is right-handed. So what is the role of the loader drive axle?

1. The transmission output shaft to further increase the torque, while the input power to change 90 ° direction to the wheels, and through the bridge on the main drive, differential, half-shaft and wheelside reduction transmission machine will be the transmission output shaft to reduce the speed, and thus produce traction.

2. Differential can make the loader in turning driving left and right drive wheels have a reasonable speed difference, so that the wheels on the ground to maintain pure rolling, in order to facilitate steering and reduce tyre wear.

3. When the loader is operating, the various loads it is subjected to are transmitted to the wheels through the axle, while the axle also transmits the traction resistance, braking resistance and lateral resistance to the frame by the wheels.

4. The axle housing of the drive axle can play the role of load-bearing and force transmission.

Choosing the Correct Forklift Carriage Class for Your Business Needs

Choosing the Correct Forklift Carriage Class for Your Business Needs

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

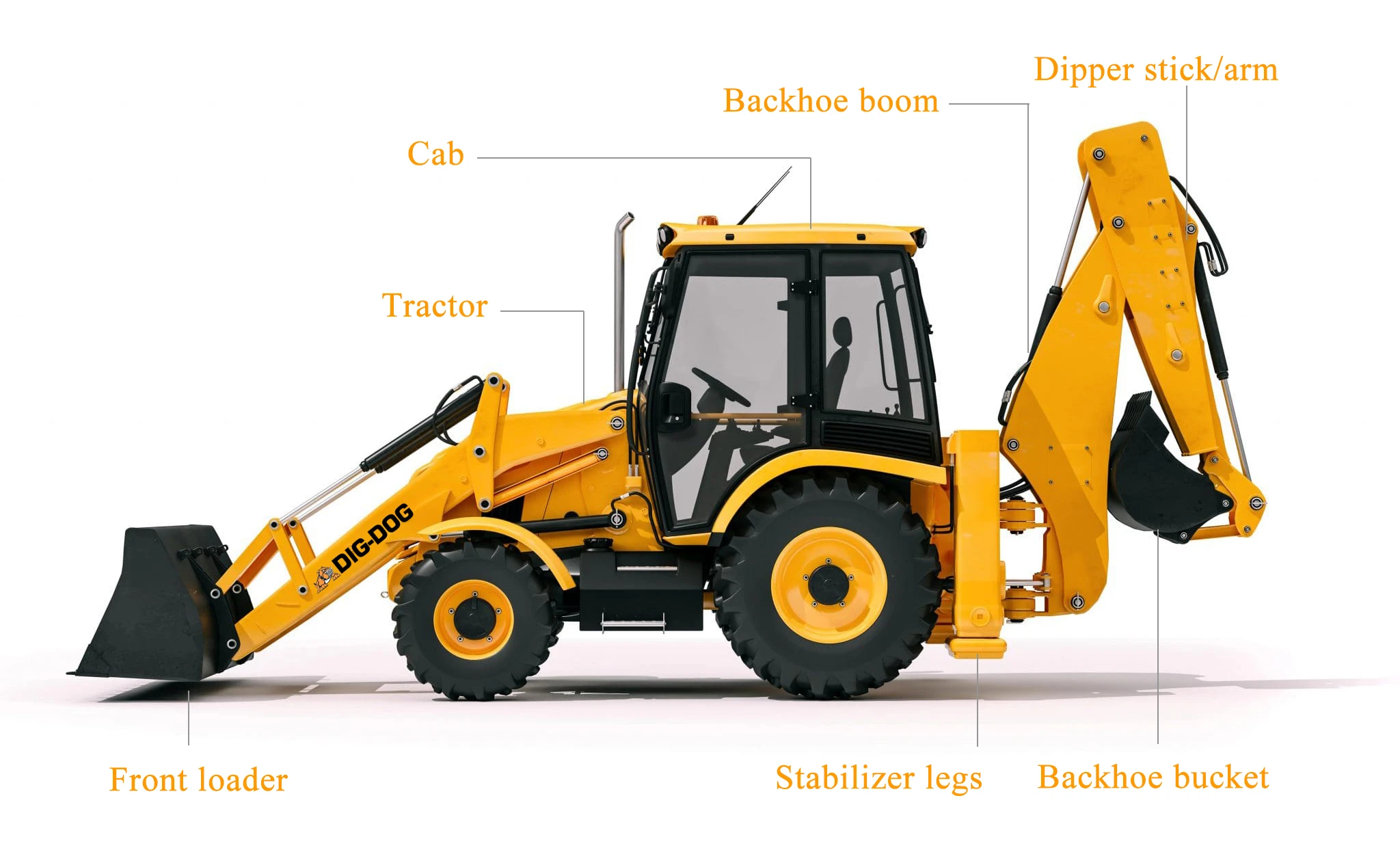

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development