Stand-on skid steers have been growing in popularity over the years as contractors realize the abundance of benefits that these machines provide — such as versatility, reliability and increased jobsite efficiency.

Two key machine components that make these benefits possible are the attachments and tracks. With a wide variety of attachment options, you need just one machine and multiple attachments to complete almost any task. Additionally, stand-on skid steer tracks improve machine performance on a jobsite, effectively increasing efficiency on your jobsite.

To ensure that a stand-on skid steer is operating efficiently, it is crucial that attachments and tracks are operating correctly, and a regular maintenance schedule is maintained for hydraulic systems. Following best practices and performing proper maintenance will ensure these parts, and in turn, your stand-on skid steer, are operating at Optimum Performance.

Each attachment available for stand-on skid steers has its own maintenance routines. Reading the operator’s manual will help you understand routine maintenance best practices for attachments, enabling you to improve machine efficiency and longevity. The most common attachments and their recommended maintenance include:

Pallet forks: Inspect forks before each use for damage or wear that requires immediate attention

Plows: Inspect for loose hose or fittings, and check the blade for wear or cracks

Tillers: Lubricate the bearings and inspect tines for damage

Trenchers: Check for worn teeth and proper chain tension in order to reduce the amount of binding

Other important considerations include the attachment lock pins for the loader arms, which should be checked whenever an attachment is installed. These pins are responsible for engaging the attachment. You can ensure a proper installation by checking whether the bottoms of lock pins are visible under the attachment receiver plate.

You should also examine where the hoses couple to the machine for dirt or debris. Contaminated quick-couplers can lead to hydraulic system failure even for machines designed to filter the fluid coming from the attachment.

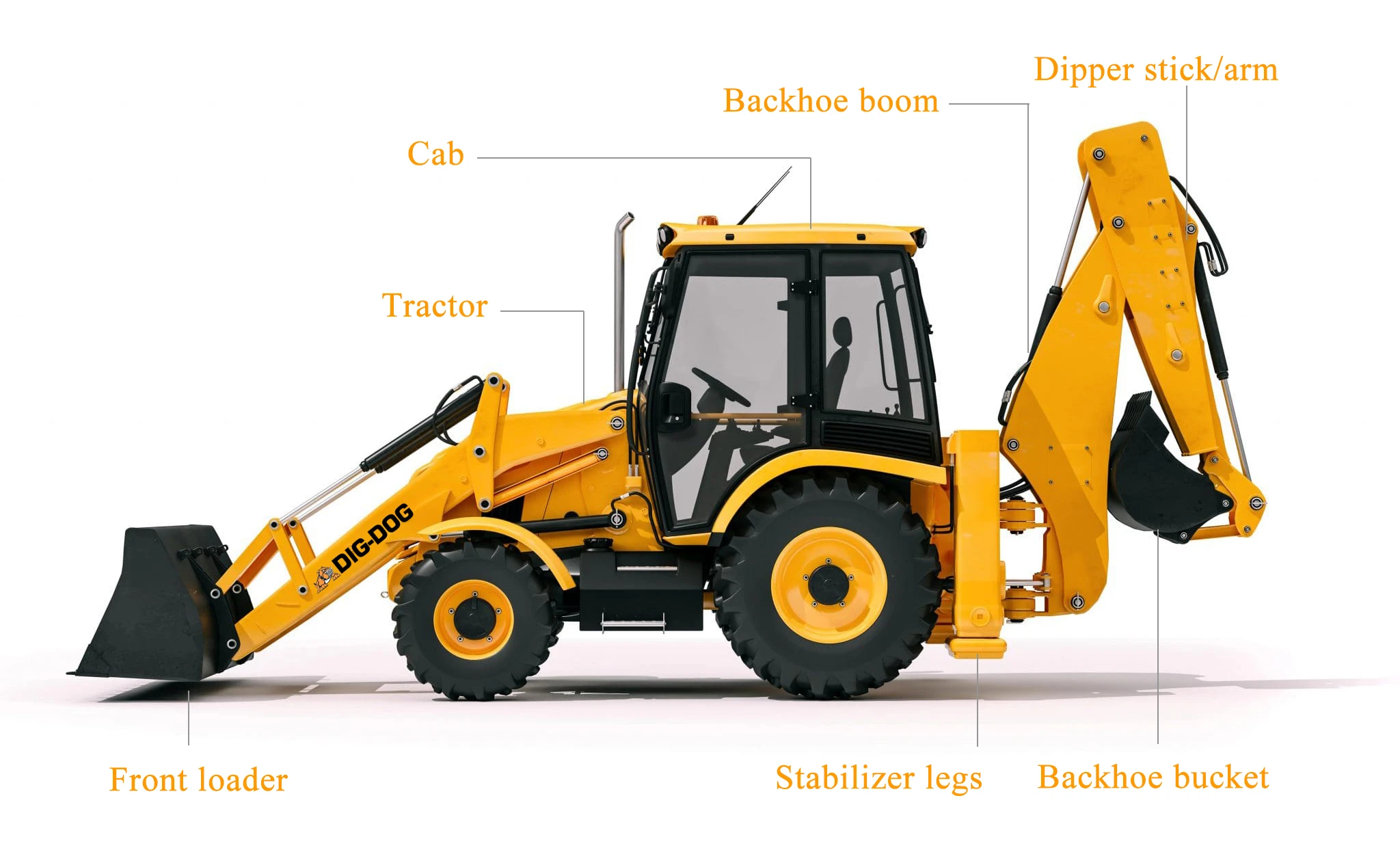

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?

Choosing the Right Loader Truck for Your Business Needs

Choosing the Right Loader Truck for Your Business Needs

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business