Diesel forklift trucks offer several advantages, including their suitability for outdoor use in wet or damp weather, less downtime as they can be quickly refueled, convenience in terms of parking, superior performance and power for handling heavy loads, cost efficiency, better visibility for the operator, and lower maintenance requirements. However, there are also some disadvantages to consider, such as noise and fume emissions, the larger size and bulk of diesel models, the need for a bulky fuel tank, higher initial cost, and potential challenges in finding diesel fuel in some areas. It is important to weigh these pros and cons against your specific needs and operating environment when considering a diesel forklift truck.

Advantages of forklifts powered by diesel include:

Great for outdoor use. Diesel forklifts are not adversely affected by wet or damp weather.

Less down time. If gas level is low, you simply fill the tank. No need to lose time charging a battery.

Convenience. A diesel forklift can be parked anywhere.

Better performance. Acceleration, forklift speed, driveline torque at low RPM, and other performance capabilities are superior and it can easily handle any hydraulic additions.

More power. Diesel lifts are more powerful and cost less to operate.

More loading capacity. Diesel forklifts are considered better in industrial applications or carrying heavier loads.

More cost efficient. The cost of diesel is usually less than propane and diesel lifts feature a lower cost of ownership than propane.

Better visibility. There is nothing blocking the operator’s rear view.

Less maintenance issues. A diesel forklift requires less scheduled and repair maintenance and has longer engine life compared to propane models.

Here are some disadvantages of a Diesel Forklift to consider.

Noise and fume emissions. This could be an issue when the lifts are used primarily indoors. Emission limiting accessories can be added, but they can be quite costly.

It’s larger and cumbersome. The diesel models size and bulk may cause a problem in a cramped warehouse and requires more space if it is stored inside a warehouse.

A bulky fuel tank. You may be required to pay extra for the tank that stores the diesel fuel.

More brake wear. Unlike electric forklifts, the driver of a diesel forklift is required to apply the brakes more often.

Waste fluids to recycle. Unlike electric lifts, diesel lifts require engine, transmission, and coolant fluid changes.

Higher initial cost. Diesel forklifts generally have a higher upfront cost compared to electric or propane-powered forklifts.

Limited availability of fuel. In some areas, finding diesel fuel may be more challenging compared to other types of fuels, such as propane or electricity.

Despite these disadvantages, diesel forklifts remain a popular choice for many industries due to their outdoor capabilities, power, and cost efficiency. It is important to carefully consider your specific needs and operating environment before making a decision on the type of forklift to invest in.

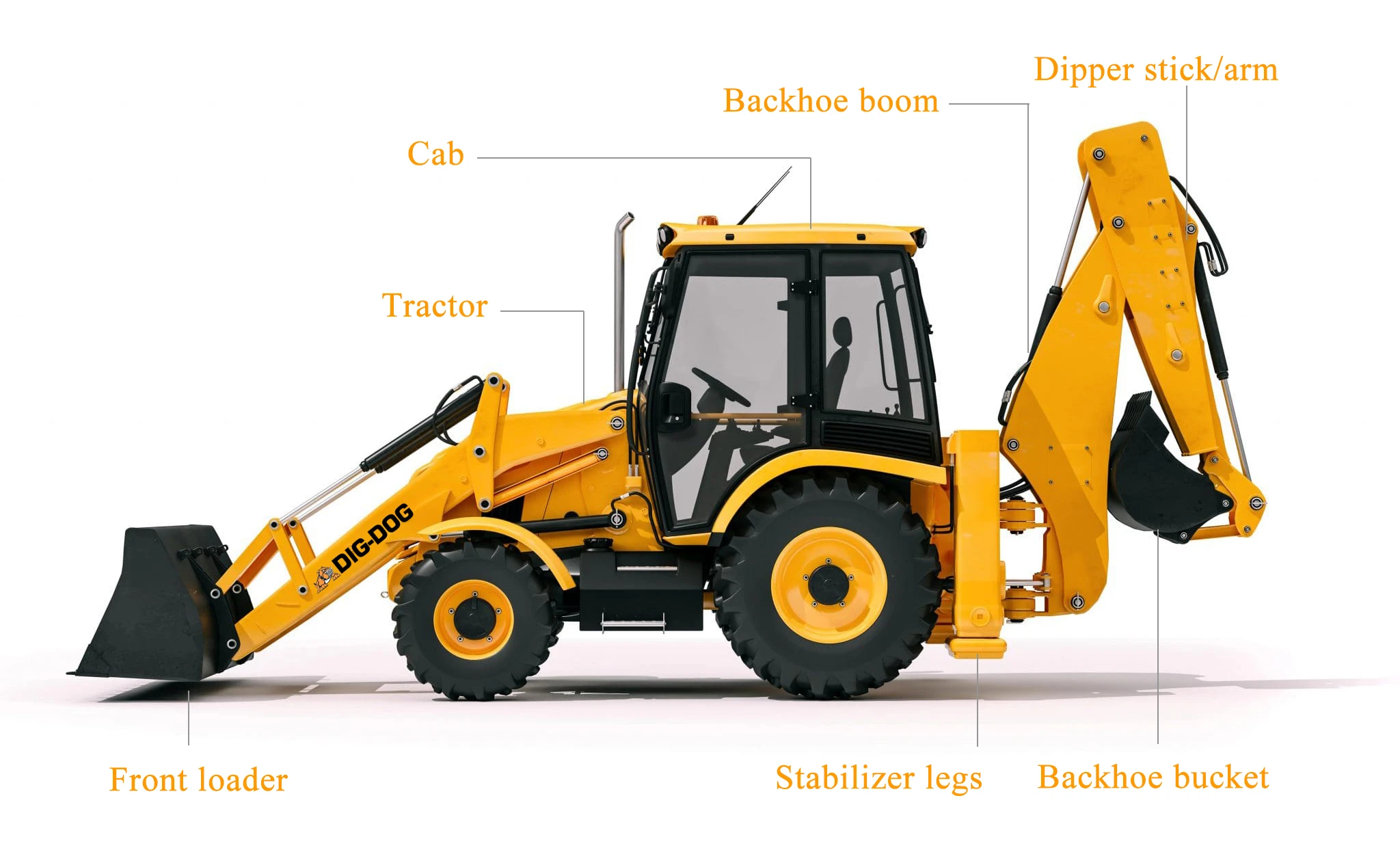

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?

Choosing the Right Loader Truck for Your Business Needs

Choosing the Right Loader Truck for Your Business Needs

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business