The key to making the right wheel loader purchase is knowing what work you’ll do with it, and then specifying a machine that delivers durability and capacity.

when specifying a wheel loader,The following is a checklist of factors that should be considered:

when specifying a wheel loader,The following is a checklist of factors that should be considered:

1 Material density determines bucket choice

A wheel front end loader’s bucket is typically its biggest revenue generator, its size and capacity is important; A bucket properly matched to its material, partnered with adequate lift capacity and dump height, could reduce the number of passes needed to fill trucks or stockpile.

“There is a tendency for contractors to buy the size of wheel front end loader they think they need and use a standard bucket,” This mindset negatively impacts productivity. Before you even select a machine, it’s important to first determine daily production targets. The next step is to look at the density of the material and match it to the size and capacity of a bucket, at last look at the machine needed to get that job done.”

While contractors may be working with multiple material densities — sand one day, rock the next — it’s important to spec the bucket based on the heaviest material it will handle.

2 Durable designs increase reliability

Durability is demanded on all job sites, but it’s particularly significant when machines are performing initial site preparation, such as clearing a wooded area. The brush and vegetation that wheel loaders encounter in this rigorous application require machines to be engineered and manufactured to protect hydraulic hoses and other important components. Additional precautions may also need to be incorporated, such as under guards and shields for front glass and lights for the wheel front end loader.

Uptime and productivity are further increased in those conditions by matching tires to withstand the rugged conditions. Determining if a more aggressive tread or wider tire for flotation is needed will help to increase productivity. Also, figuring out if a certain type of tire fill is required will further increase uptime.

3 Attachments expand versatility

The key to getting the most productivity from a wheel front end loader is the investment in a quality attachment quick-change mechanism — which is optional on most manufacturers’ machines. Many of the efficiencies are gained from operators being able to rapidly change attachments with a quick coupler from the comfort and security of a cab. Additionally, some coupler systems have been designed to eliminate greasing, requiring less maintenance and fewer replacement parts.

Loader-specific attachments have increased the versatility of these heavy-duty wheel front end loaders.

They are ideal for a range of all-purpose material handling buckets to heavy rock buckets for more serious applications. Wheel loaders can also be fitted with pallet forks and grapples.

4 Power and efficiency drive productivity

wheel front end loader productivity is defined a number of ways, but the two most common metrics are machine horsepower and lifting capacity. Optimum hydraulic performance improves cycle times, leading to increased productivity.

As a top wheel front end loader manufacturer DIG-DOG company always supporting builds long-term satisfaction.Find a dealer that is dedicated to helping contractors meet deadlines and minimize downtime with parts availability and maintenance.DIG-DOG Company can recommend a parts stocking list for frequently used wear parts to quickly provide parts that the dealer may not have on hand or regularly stock.

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

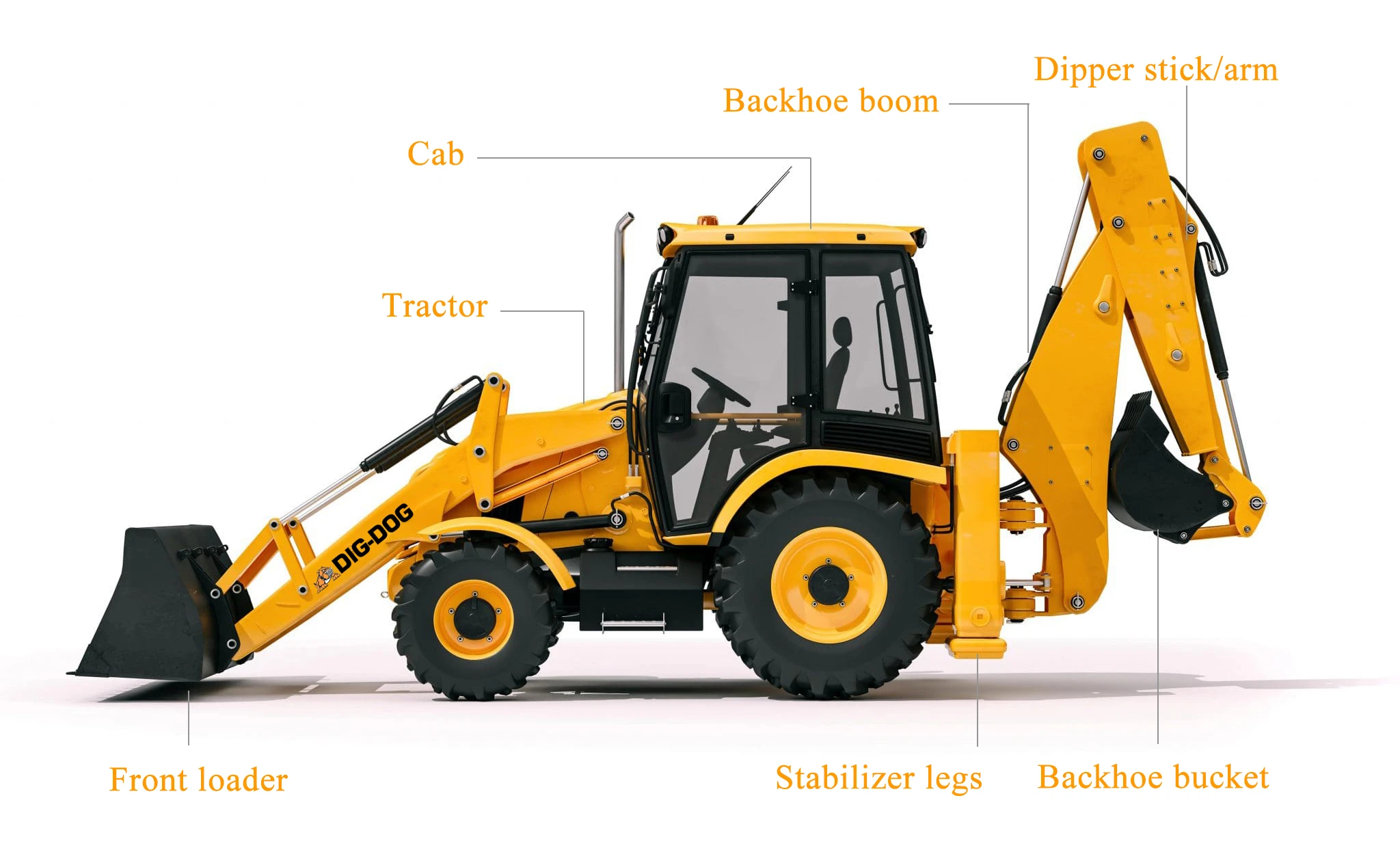

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?