A small amount of time spent caring for your mini stand on skid steer will save you the significant lost time, money, and productivity of a major repair. You’ll also save by getting more hours out of your equipment and needing to replace it less often.Preventive maintenance isn’t a chore so much as an investment.

The mini stand on skid steer loader maintenance is specific to each machine and can differ by each products’ features and design.Includ daily inspection, maintenance after use, Inspection Before firing up.

Daily inspection

A general recommendation is for a daily inspection as part of a preventative maintenance plan, checking for small issues before they become larger ones.

Maintenance after use

It is vital to perform routine maintenance after each use to ensure the continued performance and increased longevity of the equipment.

Inspection Before firing up

Perform a Thorough Visual Inspection: A user will want to inspect the entire machine for damage or wear. This includes a visual inspection of the tracks or wheels, fittings, body, controls, guards, and any attachments.

Check the tire pressure or track tension: Inspect battery terminals for corrosion, and loose or chafing wires. When cleaning battery terminals, remove the negative terminal first and install last. Inspect and replace any belts that are cracked. Also take a good look at the fuel lines, and make sure that there are no leaks.

Check and Top Off Fluids: Make sure engine oil, gasoline (or diesel), battery water and hydraulic fluid are all at the correct levels. Top off the fluids, if necessary, and be careful not to overfill. If the hydraulic fluid is a milky color, that’s an indicator that there is water in the system. This may not seem like a huge issue, but as the machine heats up, water in the system will turn into steam that can cause serious damage to the pump and wheel motors.

Keep Filters Clean: The air filter is made up of the canister, indicator, pre-filter, and main filter. Make sure to clean the canister prior to opening it to inspect or service the pre-filter or the main air filter. Some air filter systems are fitted with a service indicator mounted on the outside of the canister. The service indicator is the first indication of the air filter condition. If the filter is restricted, the inside indicator will block the clear viewing window. The air filter will need to be inspected and changed on a regular basis.

Replace the carbon canister? EPA standards have changed over the past few years, and many engine systems now have a component called a carbon canister, which collects fumes from the fuel systems. The carbon canister has a service life and needs to be replaced every 200 hours or sooner if the canister becomes restricted with dust, dirt or saturated with fuel.

Lubricate Properly and Tighten Connections: Grease all pivot points and tighten all nuts and bolts before heading out into the field. There are a lot of possible issues that can arise from loose parts. By doing a simple check with a wrench before using the compact tool carrier, it will reduce wear and extend the life of the machine’s components.

Safety Check: Make sure the parking brake is engaged (if applicable), and that the traction control lever is returned to neutral. Also make sure that auxiliary hydraulics are disengaged, as many compact utility loaders or mini skids, will not be able to start with the auxiliary hydraulics engaged.

Routinely performing basic maintenance tasks on a mini skid steer, helps maintain peak performance. By following a set routine before and after every use and performing regularly scheduled maintenance, good habits can help to reduce the risk of equipment failure.

Exploring the Cheapest Excavators with Top Performance

Exploring the Cheapest Excavators with Top Performance

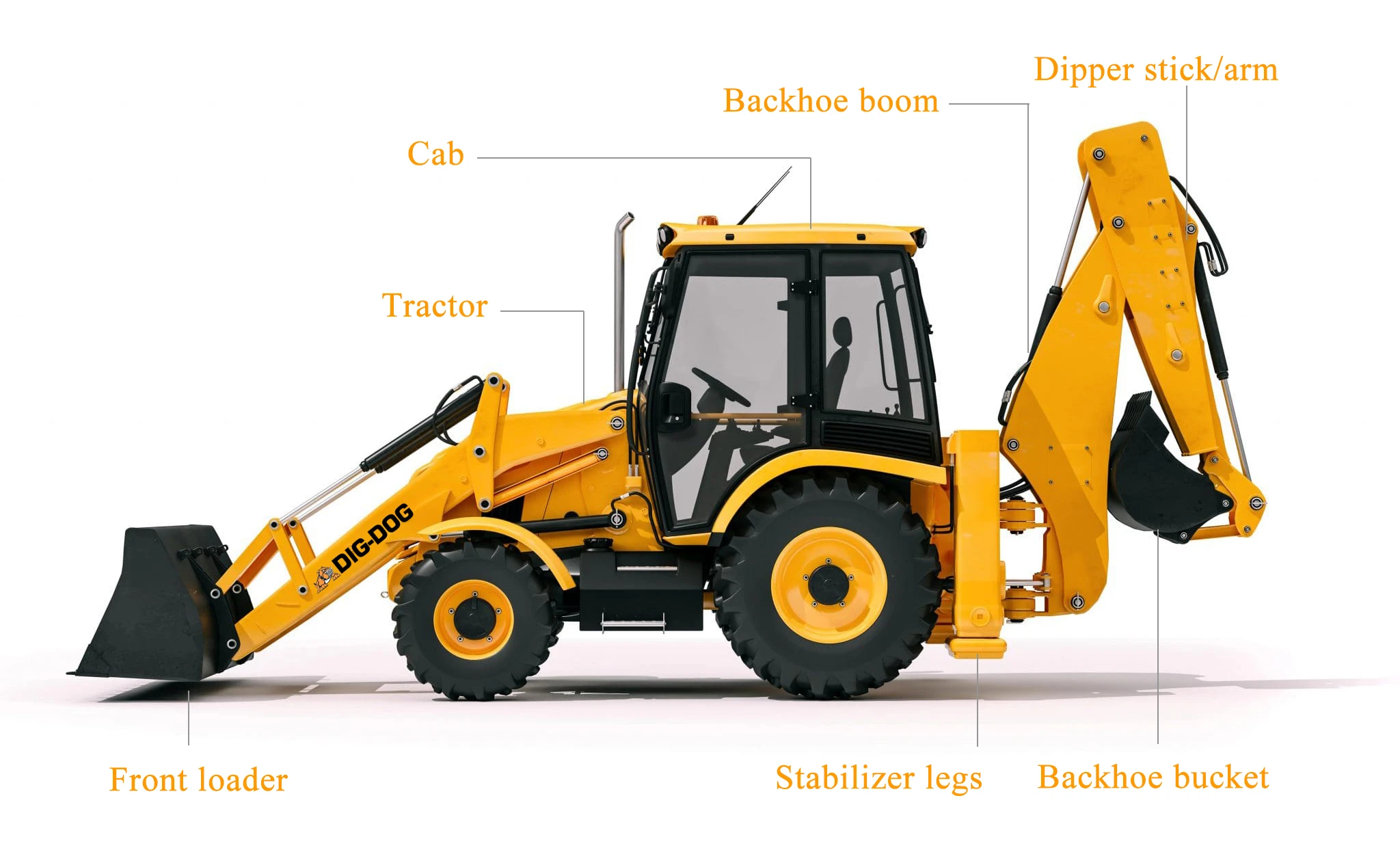

What is a Backhoe? Its Uses & Market Development

What is a Backhoe? Its Uses & Market Development

What Is The Difference Between An Excavator And A Backhoe?

What Is The Difference Between An Excavator And A Backhoe?